- Home

- Sustainability

- Society

- Health and Safety

Health and Safety

Basic Stance/Policy

- We consider the improvement of occupational health and safety to be one of the most important issues for the Production Division, and as we conduct our business activities at each factory, we promote the creation of a safe, healthy, and comfortable workplace by eliminating harmful work environments that may lead to injury or illness.

- We continuously improve our health and safety management system by setting appropriate occupational health and safety goals at each factory and reviewing them annually.

- We strive to improve occupational health and safety by complying with laws such as the Industrial Safety and Health Act and rules relating to occupational health and safety established by the company and workplace.

- Each facility eliminates hazards and causes of harm in the workplace through risk assessments and promotes activities with the goal of completely eliminating all potential hazards.

- Each facility promotes the occupational health and safety management system with the active participation and consultation of all employees.

- We acknowledge that the occurrence of accidents and injuries is a direct reflection of the nature and culture of the workplace, and we promote activities to develop correct habits through the use of the occupational health and safety management system.

- This occupational health and safety policy is disseminated to all employees at each plant through education, training, and awareness campaigns, and we facilitate the timely release of information relating to occupational health and safety within and outside the Production Division.

In order to achieve a safe and comfortable workplace and zero workplace accidents, we conduct activities to raise awareness of safety in particular through education and training. We ensure that all employees at each production facility have the mindset for an accident-free workplace, and we disclose information on occupational health and safety in a timely manner. Next year and beyond, we will continue to promote health and safety activities and obtain information on revised laws and regulations at all times. The Kofu plant achieved 3.1 million consecutive accident-free hours* in August and is in the process of applying to the Kofu Labor Standards Inspection Office for class 1 certification. In April, THK RHYTHM’s Hamamatsu plant achieved 13.2 million accident-free hours, and in July, the plant received a class 4 accident-free record certificate from the Hamamatsu Labor Standards Inspection Office.

- * Accident free hours: Number of employees × total labor hours

Policy

Create a pleasant work environment with zero work-related accidents or illnesses.

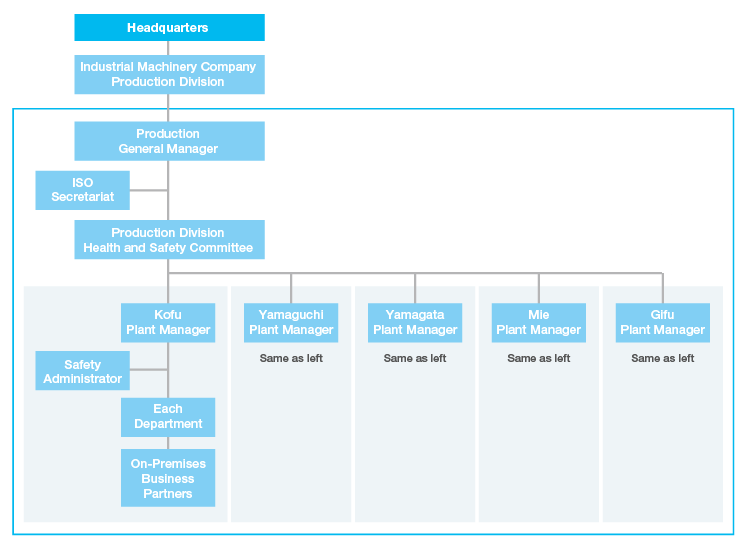

Health and Safety Management Structure

Activities and Results (Including Goals)

2021 Occupational Health and Safety Activities in the Production Division

Each production facility has established concrete goals and activities to create a pleasant work environment with zero work-related accidents or illnesses. We also pour our efforts into conducting monthly health committee meetings and health and safety patrols, as well as education campaigns that include health and safety seminars. We are strengthening our collaboration with occupational physicians with regard to metal health, such as by referring employees to specialists as necessary.

Scroll left or right to view.

| Objective | No. | Activity |

|---|---|---|

| Prevent work-related injuries and illnesses ● Work-related accidents: 0 ● Achieve 3.1 million hours without any accidents(class 1 accident-free record) |

1 | Implement risk assessments |

| 2 | Conduct workplace health and safety training | |

| 3 | Promote hazard prediction training and submission of proposals to prevent near misses (production: 1/month per group, support: 1/month per department) | |

| Continuously improve occupational health and safety performance | 4 | File and provide up-to-date information pertaining to relevant regulations (chemical substance risk assessments) |

| 5 | Promote health and safety committee activities | |

| 6 | Perform internal audits and management reviews | |

| 7 | Promote traffic safety activities (achieve zero traffic accidents) | |

| 8 | Conduct workplace safety patrols | |

| Provide a safe and healthy workplace | 9 | Promote mental health |

| 10 | Receive guidance from industrial physicians and implement disease prevention activities | |

| 11 | Perform regular and special health checks | |

| 12 | Manage long work hours (overtime) |

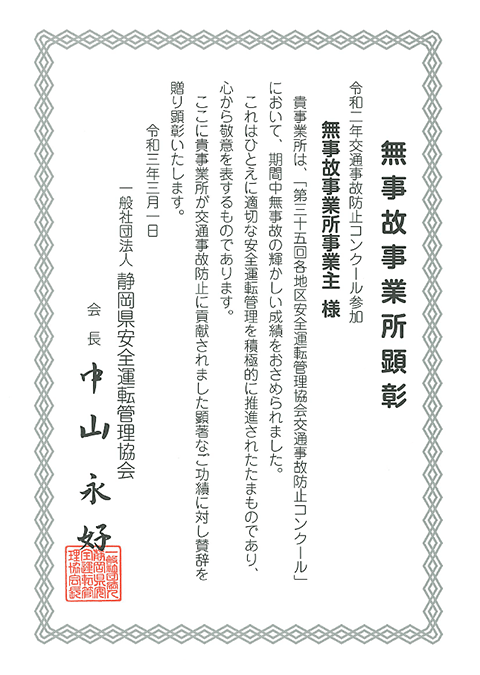

Safe Driving Award

In March, the THK INTECHS Mishima Plant was presented with an award from the Shizuoka Prefecture Society for Safe Driving Management in recognition of having an accident-free record during the eligibility period for the 35th All-District Shizuoka Prefecture Society for Safe Driving Management Traffic Accident Prevention Contest sponsored by the prefecture between October 1 and December 31, 2020.

Safety Activities

DALIAN THK thoroughly manages safety in order to achieve zero accidents and zero disasters. Since March, they have been conducting Safety Dojo training for all employees, and a total of 913 people have participated. Meanwhile, 87 employees in leadership roles participated in four seminars in June, including practical training on a responsibility system for safe production and identifying safety risks on the plant floor.

In addition, they looked for risks originating from plant equipment and the risk of electric shock in the area, adding safety fences and sensors as well as making electrical modifications. The plant will continue to identify risks and reevaluate its work standards and related rules.