- Home

- Sustainability

- Society

- Strengthening Customer Support

Strengthening Customer Support

Sales Activities

Policy

- Increase market share Strengthen collaboration between global branches

- Enter new markets Generate new demand

- Strengthen proposal-based sales Discover customers’ problems and propose solutions

Our company name incorporates three principles: Toughness (tough, durable products), High Quality (the world’s top-quality products), and Know-how (expertise for our customers). Under these principles, we conduct our daily sales activities with a customer-focused approach where we think, act, and verify results from the customer’s perspective. Currently, we have established an integrated production and sales structure with 122 sales offices and 37 production facilities close to centers of demand in order to produce and sell locally in four regions: Japan, the Americas, Europe, and Asia.

In the past few years, we have been expanding into fields that are different from our conventional ones in order to implement continuous initiatives in new business areas. Due to the influence of the coronavirus pandemic, we have been actively entering the medical device industry since last year, and our products have been adopted for use in many new pieces of equipment such as PCR testing machines. As we did last year, we held meetings with customers online in order to conduct business activities even during a state of emergency. For exhibitions outside of Japan as well, although there were time differences, we used the internet to link Japan with local sites, meet with outside executives, and conduct technical discussions.

Next year and beyond, we will maintain a sales attitude that is in line with market trends and considerate of customers.

Scroll left or right to view.

| In-person | Online | |

|---|---|---|

| Technical seminars | 0 | 52 |

| Exhibitions in Japan | 19 | 9 |

| Exhibitions outside of Japan | 6 | 2 |

| Private shows | 13 | 3 |

Activities and Results

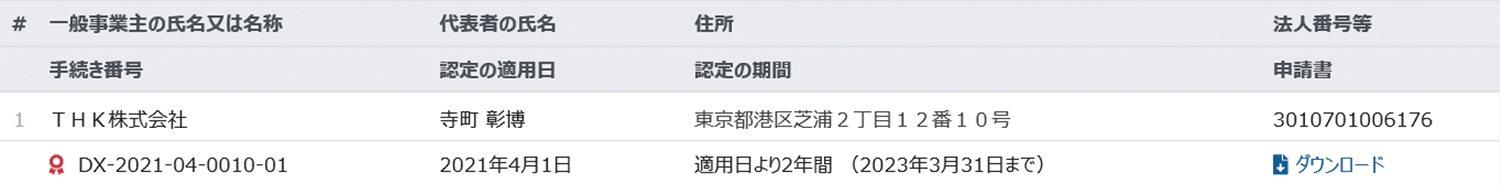

DX-Certified Operator

In April 2021, THK was accredited as a DX-certified operator through the Ministry of Economy, Trade and Industry’s Digital Transformation (DX) Certification initiative, which aims at promoting DX among businesses.

The DX Certification system is based on the Partial Revision of Act on Facilitation of Information Processing, which came into effect on May 15, 2020. This is an accreditation for business operators that have formulated a vision for promoting DX and established a strategy and formal structure.

Autonomously Moving Signage Robot ( ) Selected for Robot Demonstrations

) Selected for Robot Demonstrations

THK’s autonomously moving signage robot combines a digital display with an autonomously moving trolley that can move in all directions and turn 360° in tight spaces. It can be used to display multimedia content, and it can be operated remotely. This year, this robot was selected for demonstrations in Aichi Prefecture and Kanagawa Prefecture.

Example Application in Aichi Prefecture

This product was selected for the AICHI ROBOT TRANSFORMATION demonstration in January sponsored by Aichi Prefecture. As the coronavirus pandemic has brought service robots to the forefront as a new part of daily life, this proof-of-concept trial showed successful examples of using robots that collaborate with people in various scenarios.

This year, THK’s robot was selected for a proof-of-concept trial at Toyota Stadium, demonstrating its use as a mobile advertising pillar and a means to provide administrative support remotely.

Example Application in Kanagawa Prefecture

In September, THK’s robot was selected for the guiding robot trial conducted at the Okinawa Tokushukai Shonan Kamakura General Hospital as part of Kanagawa Prefecture’s 2021 Project for the Implementation of Robots as a Coronavirus Countermeasure.

The purpose of the trial at the hospital was to guide visitors to examination rooms or other destinations through remote operation or the robot’s autonomous movement function. The height of the display could also be adjusted through remote operation to match the height of the visitor and allow the operator to communicate with them more directly.

Registered in a Database

In April, the LM Guide Model LSR we developed in 1972 as the world’s first commercial product of its kind was registered in the History of Japanese Industrial Technology database* maintained by the National Museum of Nature and Science in Japan.

The entry recognizes the Model LSR for using our proprietary technology to enable the linear motion of machines through rolling motion and becoming the world’s first commercialized linear motion guide (LM Guide), which drastically improved machine performance. This greatly contributed to the linear motion guide’s widespread adoption and proliferation within Japan’s key machine tool and semiconductor industries.

- * History of Japanese Industrial Technology database: A collection of valuable materials related to the development of technology in post-war Japan. This online database is maintained by the National Museum of Nature and Science’s Center of the History of Japanese Industrial Technology in order to preserve this history for future generations.