- Home

- Sustainability

- Environment

- Conserving Energy and Preventing Global Warming

Conserving Energy and Preventing Global Warming

TCFD Information Disclosure

The THK Group has identified climate change as a material issue (significant challenge), and as of February 2023, it has become a supporter of the TCFD (Task Force on Climate-Related Financial Disclosures) recommendations. The TCFD recommendations are structured around the four core elements of governance, strategy, risk management, and metrics and targets. In accordance with the TCFD recommendations, THK has analyzed the impact of climate change on its business.

Governance

THK has established a Sustainability Committee, headed by the CEO, that investigates and discusses risks, opportunities, and responses related to climate change and acts as an advisor to the Board of Directors.

As an organization beneath the Sustainability Committee, the Sustainability Promotion Subcommittee is made up of representatives of each business division, and they analyze scenarios related to climate change risks and opportunities in accordance with the TCFD recommendations.

The Sustainability Committee confers on the results of the analysis performed by the Sustainability Promotion Subcommittee, determines measures to respond to climate change, and monitors the progress.

Based on the items discussed and resolutions determined by the Sustainability Committee, the Board of Directors receives and discusses reports and proposals as appropriate and provides general supervision for the climate change efforts of each division.

Strategy

Based on 1.5°C and 4°C climate change scenarios proposed by the IEA (International Energy Agency) and IPCC (International Panel on Climate Change), the THK Group has been analyzing scenarios primarily with regard to its Japanese industrial machinery business and automotive and transportation business in consideration of their long-term impact up to 2050 in order to investigate strategies and the resilience of those strategies with reference to climate change risks and opportunities.

- * 1.5°C scenario: Scenario in which regulations for minimizing global warming are strengthened and market changes are enacted (IEA NZE, IPCC AR6 (Sixth Assessment Report) SSP1-1.9, etc.)

- * 4°C scenario: Scenario in which physical impacts such as extreme weather events result from global warming (IPCC AR5 (Fifth Assessment Report) RCP8.5, etc.)

Primary Climate Change Risks/Opportunities and Responses

Scroll left or right to view.

| Scenario | Cause | Change | Risk/Opportunity | Level | Impact on THK | THK’s Response |

|---|---|---|---|---|---|---|

| 1.5°C | Introduction of carbon taxes |

Increased procurement costs |

Risk | Major | The introduction of carbon taxes will cause raw material price increases to be passed on to THK, and procurement costs will rise. | ▶Reduce raw material input ▶Switch to raw materials with low carbon taxes |

| Increased operating costs |

Risk | Major | The introduction of carbon taxes will cause carbon tax payments to increase based on Japanese Scope 1 and Scope 2 emissions. | ▶Develop energy-saving production technology ▶Transition to low-carbon, non-fossil fuel energy |

||

| Change to renewable energy | Increased energy procurement costs |

Risk | Major | The change to renewable energy will increase energy procurement costs. | ▶Procure renewable energy internally by installing solar power generation systems | |

| Increased need for energy savings | Increased demand for environmentally friendly technology solutions | Opportunity | Major | There will be more equipment designs, fabrications, modifications, and product demand for automation and efficiency improvements for the purpose of boosting energy efficiency. | ▶Strengthen provision of THK products that contribute to energy savings (LM Guide, electric actuators, unit products, etc.) | |

| Increased business opportunities in semiconductors | Opportunity | Major | Business opportunities will increase for the manufacture of semiconductor manufacturing equipment components, particularly involving power semiconductors, which form the core of energy savings. | ▶Establish a development, production, and sales structure that can respond promptly and flexibly | ||

| Increased demand for failure diagnosis/predictive failure detection service | Opportunity | Minor | Demand will increase for a failure diagnosis/predictive failure detection service that utilizes the IoT and helps boost productivity and reduces energy loss. | ▶Expand IoT services that boost productivity and strengthen sales activities and solutions that utilize such services | ||

| Advancement of electric vehicles | Increased demand for electric vehicle components | Opportunity | Major | As more vehicles become electric, new types of products become required, and demand for THK products will increase. | ▶Establish a development, production, and sales structure that can respond promptly and flexibly ▶Plan new business |

|

| Expansion of environmental business | Increased ESG investment | Opportunity | Minor | Expanding THK’s business in environmental fields will capture the attention of investors and make them evaluate THK more favorably, and ESG investment will increase. | ▶Establish a development, production, and sales structure that can respond promptly and flexibly

▶Actively disclose information and strengthen communication with stakeholders |

|

| 4°C | Serious damage from weather-related disasters | Supply chain interruptions | Risk | Minor | Supply of raw materials will be interrupted if the supplier suffers a disaster. | ▶Decentralize raw material suppliers ▶Secure alternative suppliers |

| Increased costs from global warming | Risk | Minor | Rising temperatures will cause air conditioning costs to increase for factories, distribution centers, and offices. | ▶Improve heat insulation performance of buildings |

Risk Management

In terms of overall risk management, the Risk Management Committee, which serves as an advisor to the Board of Directors, comprehensively and exhaustively identifies and assesses risks in accordance with risk management regulations, evaluates their severity, and determines the priority for addressing them.

For risks related to climate change, the Sustainability Committee and the Sustainability Promotion Subcommittee, which is under the Sustainability Committee, conduct an analysis of scenarios specific to climate change, identifies risks, and evaluates them in order to determine countermeasures.

Based on the risks and measures identified by the Risk Management Committee and the Sustainability Committee, the Board of Directors coordinates the impact of climate change on the business.

Metrics and Targets

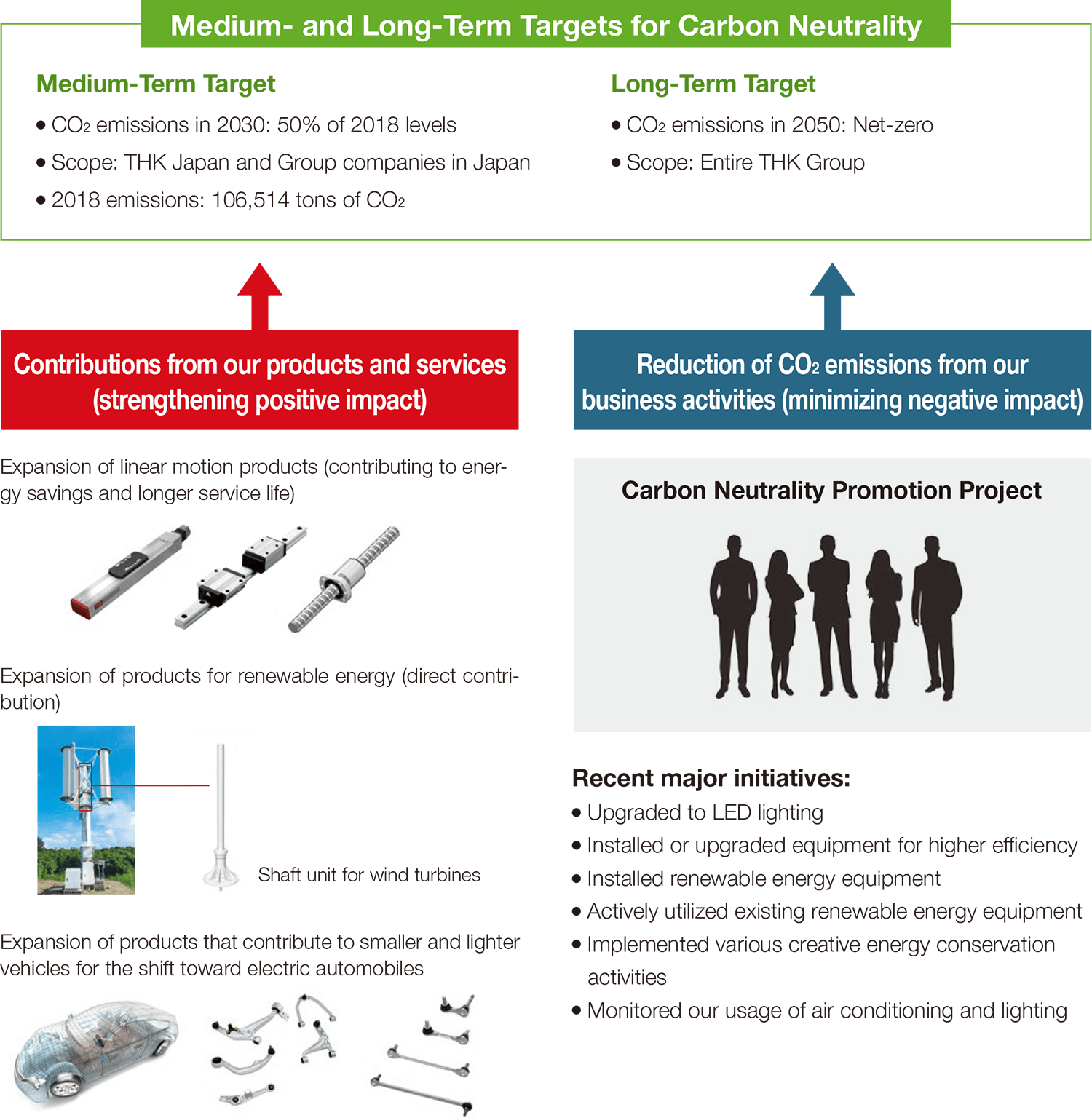

In August 2021, the THK Group formulated the following medium-term and long-term targets for reducing greenhouse gas emissions in order to combat global warming.

Medium-Term Target

By 2030, reduce CO2 emissions to 50% of 2018 levels.

Scope: THK Japan and Group companies in Japan

2018 emissions: 106,514 tons

2030 target emissions: 53,257 tons

Long-Term Target

By 2050, achieve net-zero CO2 emissions.*

Scope: Entire THK Group

- * Net-zero CO2 emissions: Achieving a balance between man-made CO2 and greenhouse gas emissions with their removal by carbon sinks such as forests.

Based on these targets, the THK Group will develop products that further contribute to energy and labor savings, continue conducting its business with environmental considerations in mind, and work to achieve a sustainable and affluent society.

THK’s Medium- and Long-Term Targets for Carbon Neutrality

The world is facing risks driven by climate change from global warming, and in response, the THK Group has established medium- and long-term targets for lowering its emissions of greenhouse gases. (These targets were approved by the Board of Directors in August 2021.)

The entire THK Group will continue to work together to promote effective policies aimed at achieving a carbon-neutral society.

As necessary, updates on these efforts will be released in an appropriate manner.

Medium-Term Target

By 2030, reduce CO2 emissions to 50% of 2018 levels.

Scope: THK Japan and Group companies in Japan

2018 emissions: 106,514 tons

2030 target emissions: 53,257 tons

Long-Term Target

By 2050, achieve net-zero CO2 emissions.*

Scope: Entire THK Group

- *Net-zero emissions: Achieving a balance between man-made CO2 and greenhouse gas emissions and their removal by carbon sinks such as forests. (Source: Ministry of the Environment’s website)

Energy Conservation Initiatives

Energy Conservation

As exemplified by sustainability, society and corporations

generate common value through corporate activities that

minimize the negative impacts and strengthen the positive.

With this mindset of working for the benefit of all in addition

to our individual interests, THK is promoting various initiatives

to achieve the creation of a sustainable society.

The world is facing risks driven by climate change from

global warming, and in response, the THK Group has established

medium- and long-term targets for lowering its

emissions of greenhouse gases. (These targets were approved

by the Board of Directors in August 2021.)

To minimize our negative impact, we have established

the Carbon Neutrality Promotion Project, which is working

to further reduce the CO2 emitted through our business

activities. Meanwhile, to strengthen our positive impact,

we are expanding our offerings of linear motion and other

products and services that contribute to energy conservation.

We will accelerate our various initiatives in order to

achieve these goals.

Activities and Results

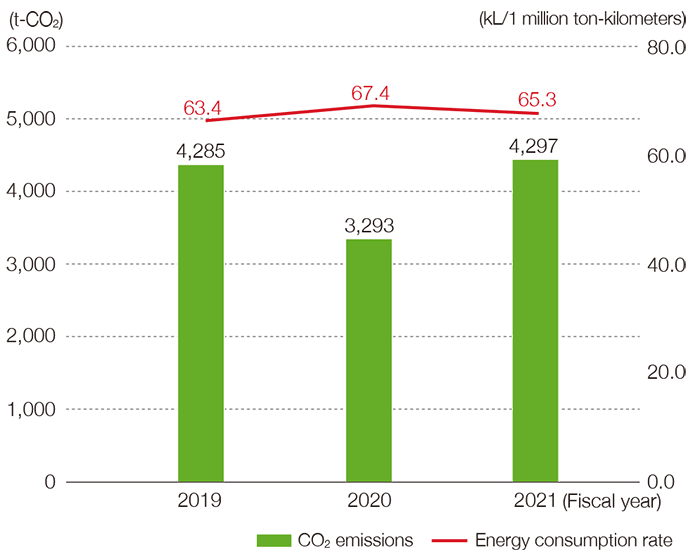

Initiatives for Green Distribution

Policy

- Propose shipping methods that minimize CO2 emissions while considering customers’ due dates

- Consider load efficiency and labor efficiency in logistics

- Reduce CO2 emissions year on year and reduce fuel consumption rate by 1% (per ton-kilometer of shipping)

Distribution departments* are constantly considering shipping methods to reduce CO2 emissions while giving top priority to meeting customer delivery dates. Since June, we have switched some overseas shipping from the conventional air freight to transport by ferry. From the next fiscal year onward, we will actively utilize DX to reduce CO2 emissions through more efficient shipping, such as by using advance understanding of shipment volumes to determine optimal loading on pallets. In addition, we will use AI to review operations and implement initiatives to save labor.

- * Distribution departments: Two distribution centers (Chubu and Yamaguchi); three factory centers (Yamagata, Kofu, and Mie); and THK NIIGATA

- * Data collection period: January to December

- * Data includes five production facilities in Japan (Yamagata, Kofu, Gifu, Mie, and Yamaguchi); two distribution centers (Chubu and Yamaguchi); and three factory centers (Yamagata, Kofu, and Mie).

Upgrading to LED Lighting

The details and results of our LED upgrades during 2021 are summarized below.

Scroll left or right to view.

| Plant | Location | Time frame | Type and number of bulbs | Reductions |

|---|---|---|---|---|

| Electricity used (kWh) | ||||

| Gifu Plant | Stair landings | June | Fluorescent: 12 | 858 |

| Yamaguchi Plant | Throughout the plant (including distribution center) | December | Fluorescent: 1,015 Mercury: 606 |

671,000 |

| THK NIIGATA Plant | Factory 3, 2nd floor Assembly/Manufacturing Promotion Unit office | July | Fluorescent: 74 | 1,733 |

| Quality Assurance Section office | July | Fluorescent: 8 | 212 | |

| Employee entrance | November | Fluorescent: 12 | 348 | |

| THK INTECHS Mishima Plant | Factory 1 clean booth line | April | Fluorescent: 17 | 628 |

| In front of Factory 2 coating area | July | Fluorescent: 12 | 264 | |

| Talk Plaza, 2nd and 3rd floors | August | Fluorescent: 226 | 7,215 | |

| THK RHYTHM Hamamatsu Plant |

Development Building, 1st and 2nd floors (all lighting) | July | Fluorescent: 116 | 9,280 |

| Machining/assembly lines in the plant, logistics office, etc. | May to July | Fluorescent: 214 | 12,840 | |

| THK RHYTHM Kyushu Plant |

Factory 1 machining and assembly lines | January to October | Fluorescent: 100 | 5,879 |

| THK America | Headquarters office | June | Fluorescent: 292 | 38,234 |

| TRA Michigan | Throughout the plant | January to October | Fluorescent: 360 | |

| THK Wuxi | Transformer substation | January to August | Fluorescent (36 W): 108 Fluorescent (45 W): 24 |

18,353 |

Efforts at Each Production Facility

Yamagata Plant

Effective Use of HVAC Equipment

The new HVAC equipment installed in Factories 4 and 5 has a forced cooling function, and the outside air intake can be at 100%, compared to the roughly 15% possible with regular equipment. Therefore, the plant made use of that ability in the cooler period from late March to mid-June and shut off the air conditioning. As a result, they were able to reduce CO2 emissions by about 5.2 tons per year, or the equivalent of about 10.6 kL of crude oil.

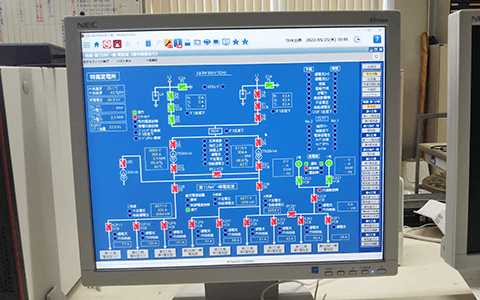

Central Monitor Used for Demand Control

Between late July and mid-August, a demand agreement was maintained by deciding equipment priorities for all machines and actively utilizing a central monitor (for power, air conditioner status, and device malfunctions) in every area from Factory 1 to Factory 6. As a result, they were able to reduce CO2 emissions by about 1.0 ton per year, or the equivalent of about 0.5 kL of crude oil.

Heat Source Improvement Work

From January to July, work was done to replace the type of fuel used for the heat source in the Factory 2 power building, switching from an oil-fired chiller-heater to an electric turbo chiller and gas-fired heater. As a result, they were able to reduce CO2 emissions by about 608.0 tons per year, or the equivalent of about 228.0 kL of crude oil.

Kofu Plant

Cooling Tower Upgrade

The building lease for the Sanwa Factory used by Manufacturing Section I was signed, and the cooling tower was upgraded in July. As a result, they were able to reduce CO2 emissions by about 6.3 tons per year, or the equivalent of about 3.6 kL of crude oil.

Insulating Ceramic Coating

Along with conducting a repair of the aging exterior walls of Factory 3 and Factory 4, an insulating coating was applied beginning in September. With the project scheduled for completion in December, the effect has been limited, but it has reduced CO2 emissions by about 7.1 tons per year, or the equivalent of 3.1 kL of crude oil.

Yamaguchi Plant

Upgrading Compressors

In June, two compressors in the grinding area of Factory 3 were upgraded to increase the discharge rate and make them high-efficiency units. As a result, they were able to reduce CO2 emissions by about 97.5 tons per year, or the equivalent of about 44.7 kL of crude oil.

Pursuing Energy-Saving Operations

Since November, the coolant air supply area in Factory 3 in Zone B has been running in energy-saving mode by using the optimal pressure for days the plant is not in operation. As a result, they were able to reduce CO2 emissions by about 4.0 tons per year, or the equivalent of about 1.9 kL of crude oil.

THK NIIGATA

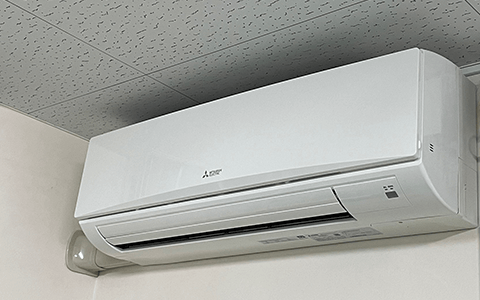

Updating HVAC Equipment

A total of eight pieces of aging HVAC equipment were replaced with new units in July, including five in the break rooms of Factories 1, 2, and 3; one in an office on the production floor; one in the Manufacturing Promotion Unit office; and one in the Quality Assurance office. As a result, they were able to reduce CO2 emissions by about 0.4 tons per year, or the equivalent of about 0.2 kL of crude oil.

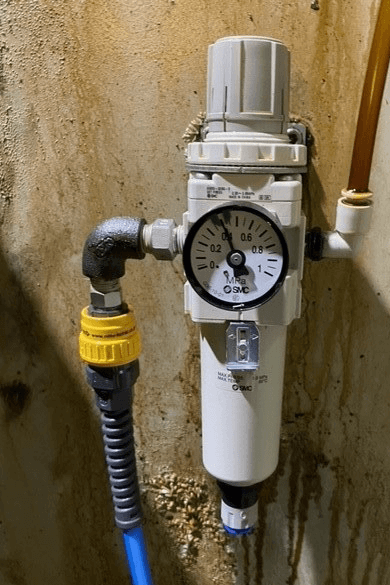

Preventative Maintenance Activity

Air leak patrols were conducted monthly, so air leaks were repaired and aging components were replaced. As a result, they were able to reduce CO2 emissions by about 8.8 tons per year, or the equivalent of about 4.2 kL of crude oil. In addition, as part of their preventative maintenance, the polycarbonate air regulator caps were gradually replaced with steel caps that will not deteriorate.

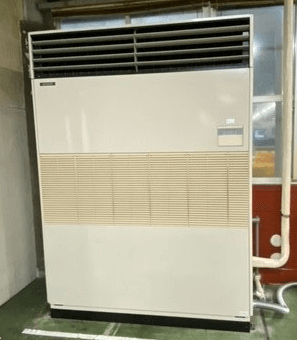

Floor-Mounted Packaged Air Conditioner

The air conditioner used in the miniature nut machining process in Factory 1 was an old unit containing R22 refrigerant,* so it was replaced with a floor-mounted packaged air conditioner in August. As a result, they were able to reduce CO2 emissions by about 2.5 tons per year, or the equivalent of about 1.2 kL of crude oil.

- * R22 refrigerant: The manufacture of this substance was completely phased out on January 1, 2020, in accordance with the Montreal Protocol and the Ozone Layer Protection Law. The air conditioner was replaced to prevent rising repair costs, lengthen the time between servicing, and avoid the risk of the unit becoming unrepairable.

THK INTECHS Mishima Plant

The Mishima plant ran a generator as an auxiliary power source for the compressors from early December 2020 to the end of March 2021 and again from early July to late September, during the times of the year with the heaviest power consumption due to heating and cooling. As a result, they were able to reduce CO2 emissions by about 15.99 tons per year, or the equivalent of about 5.9 kL of crude oil.

THK RHYTHM Hamamatsu Plant

Roof Replacement

The roof of the machining and assembly factory, made of large slate roof tiles and wood wool cement board, was replaced with ribbed Galvalume steel and Phenovaboard in September, which improved the roof’s insulating capability by a factor of about 5. As a result, they were able to reduce CO2 emissions by about 4.5 tons per year, or the equivalent of about 2.0 kL of crude oil.

Compressor Upgrade

An aging compressor was replaced in December. As a result, they were able to reduce CO2 emissions by about 11.7 tons per year, or the equivalent of about 7.1 kL of crude oil.

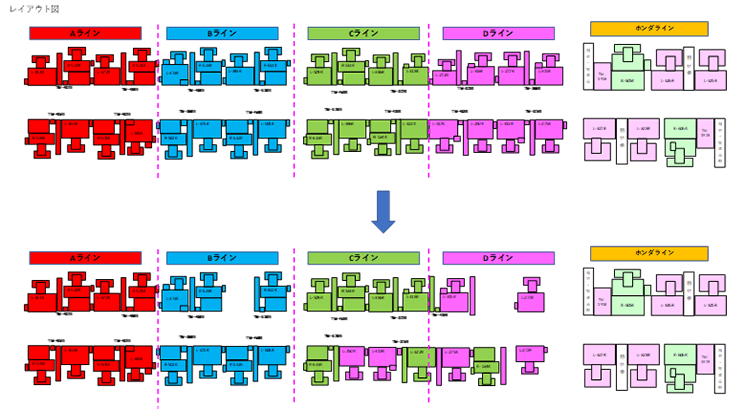

Consolidating Machines

The production lines were revised in November to improve efficiency. A concentrated layout was created for the (rack and pinion type) steering tie rod socket machining process by removing four NC lathes and two thread checkers from the line. As a result, they were able to reduce CO2 emissions by about 2.5 tons per year, or the equivalent of about 1.5 kL of crude oil.

THK RHYTHM Kyushu Plant

Dry Machining (Eliminating Coolant)

The use of coolant was eliminated from the ball stud machining line starting in November in order to reduce waste and decrease the cost of purchasing cutting oil. As a result, they were able to reduce CO2 emissions by about 8.0 tons per year, or the equivalent of about 6.2 kL of crude oil.

Reducing Loss from Rolling Machine Idling

From January to September, an energy-saving timer was installed on nine rolling machines to reduce the loss from idling. As a result, they were able to reduce CO2 emissions by about 8.5 tons per year, or the equivalent of about 6.2 kL of crude oil. The remaining three machines were scheduled to be completed by December.

TRA Michigan

In March, fourteen windows in the cafeteria were replaced with insulated glass and twenty were replaced with aluminum foam panels.