Machine tools

All the various parts used in machine tools are made by "mother machines" that produce machine parts themselves. Whether fine and complex or massive and heavy, the manufacturing precision of parts produced by machine tool is increasing at an accelerating pace. THK's linear motion systems help provide the guidance that makes this precision and speed possible.

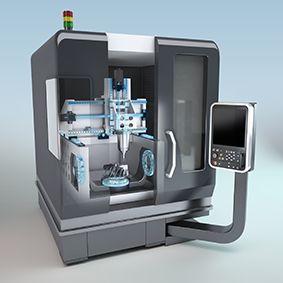

Machining centers

The leading player among cutting machines is the "machining center." Highly accurate and rigid, Caged Ball LM Guides and Ball Screws are used for the table that must position the workpiece accurately and quickly, and for the driving mechanism that moves cutting tools. In addition, Cross-Roller Rings are used for the rotary table that is required to move in a smooth rotary motion.

Milling machines

Although the machining centers and other CNC lathes are mainstream in the manufacture of mass-produced products, milling machines are still used at the cutting edge of manufacturing production. The most advanced machines, capable of making ultra high-precision products, are also produced under the fine control of craftspeople. To reproduce such craftwork, LM Guides and Ball Screws that can operate without wasted movement are used in milling machine guidance systems.

NC lathes

Along with machining centers, NC lathes also play a leading role in machining. With their high rigidity and accuracy, LM Guides and Ball Screws are essential to the movement of the lathe's tool post. Additionally, because LM Guides combine this high rigidity with very compact design, they can contribute to the miniaturization of equipment.

Plano millers

The plano miller is a large milling machine. Obviously, its workpieces are also large and heavy. However, if highly rigid LM Guides are used for table movement, the table can move smoothly and large parts can be machined with a high level of accuracy.

CNC hobbing machines

Sliding guides have traditionally been used for hobbing machines that produce gears for motion and power transfer, but piping design and lubrication management has been difficult. Using LM Guides and Ball Screws together with lubrication options, you can reduce system design work and assembly steps while lengthening the system maintenance requirement cycle.

Surface grinding machines

Until recently, hydraulic cylinders were used to feed the tables of surface grinding machines. But now that Ball Screws and servo systems are used for table feeding, this can be done with more accuracy at higher speeds, improving productivity. A machine operating with Ball Screws does not require any hydraulic system, making the machine cleaner and reducing any negative impact on the environment.

Products used

LM Guide (Linear Motion Guide)

The LM Guide (Linear Motion Guide) is our main product, incorporating a part with a linear rolling motion into practical usage for the first time in the world.

Ball Screw

The Ball Screw is a high-efficiency feed screw with the ball making a rolling motion between the screw axis and the nut.

Ball Spline

The Ball Spline is a rolling guide spline bearing.

Cross-Roller Ring

The Cross-Roller Ring is a roller bearing with high rotation accuracy capable of bearing loads in every direction.

Lubrication accessories

An assortment of lubrication associated products is available to maintain sufficient lubrication of machines.