- Home

- Sustainability

- Environment

- Promotion of Waste Reduction and Recycling

Promotion of Waste Reduction and Recycling

Achieving and Maintaining Zero Emissions

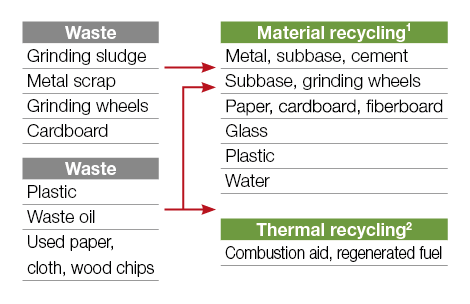

The aim of zero emissions is to recycle waste generated during production processes, switch to beneficial materials that can be put to other industrial uses, and get as close to discharging zero waste as possible. We promote zero-emissions activities through controlling the use of direct and indirect materials, emissions and final waste, and reusing and recycling.

The waste produced by our business activities includes metal scrap, oil and liquid waste, grinding sludge, packaging, and plastic waste. By thoroughly separating our waste, we reuse or transform waste into usable materials, such as by turning steel scrap into steel-making material, sludge with grinding wheel dust into cement material, and oil and plastic waste into fuel.

As we work to conserve resources and promote zero emissions, we achieved an emissions rate (volume of waste disposed/total discharged) of 0.09% in 2021, once again reaching our annual target of less than 0.50%.

- 1 Material recycling: Reusing waste as raw material for another product

- 2 Thermal recycling: Using waste as combustion material

Activities and Results Related to Plastic Waste

Efforts at Each Production Facility

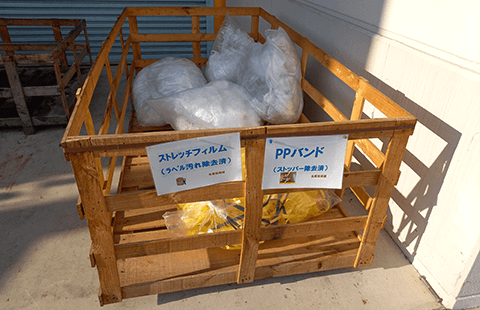

Yamagata Plant

Throughout the year, all areas in Factories 1 to 6 worked to take the stretch film and plastic bands that once were disposed of as industrial waste and instead recycle them as valuable resources. The annual total of material recycled was 1,690 kg.

Kofu Plant

Improving upon previous waste reduction measures, changes were made to the way mixed waste is separated and oily sludge is disposed of, which resulted in about a 540 kg reduction in waste plastic and a 10.8 kL reduction in waste oil for this year.

Mie Plant

The plant sends the cushioning used for packaging products at the heat treating process back to the vendor. As a result, 3,600 kg of material was recycled over the year.

THK NIIGATA

In April, all areas of the factory began breaking down and recycling plastic and plastic product boxes. They also started working with shipping companies to reuse wooden pallets. As a result, 750 kg of material was recycled over the year.

THK RHYTHM Hamamatsu Plant

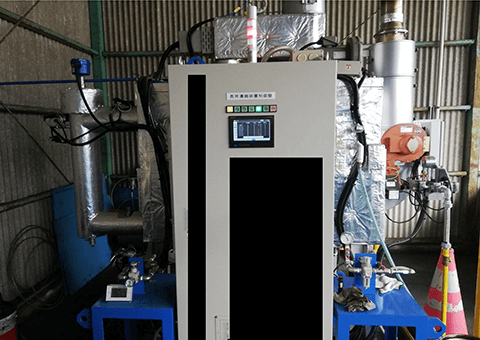

Installing a Waste Fluid Compactor

In May, a waste fluid compactor that evaporates the moisture from water-soluble cutting oil was installed in the waste storage area to reduce waste fluid (decreasing the amount of waste fluid transported for disposal and the risk of spillage outside the plant in the event of a disaster). As a result, waste was reduced by 43,800 L annually.

DALIAN THK

Installing a Waste Fluid Concentrator

In June, DALIAN THK installed a waste fluid concentrator to reduce the amount of waste from its rough machining process. The device evaporates the water content from the waste fluid at a high temperature, creating a concentrated liquid. As a result, they have been able to reduce 372 tons of waste fluid to 27 tons of concentrated fluid that was then disposed of.

THK Wuxi

Installing a Grinding Sludge Solidification Machine

The Wuxi plant installed a sludge solidification machine for Grinder Coolant Centralized Filter Device 3, which is used for the grinding process, in order to reduce the impact on the environment. As a result, they reduced the amount of grinding sludge by 75,600 kg per year (about 40% of the previous year’s amount).