LM Guide pioneers

A machine's moving parts can be classified as rolling, linear, or a combination of both. With the development of rolling bearings about 110 years ago, rolling contact became the standard method for accomplishing rolling motion. This brought about a great technological revolution. Rolling contact not only saved motion energy, but also kept frictional resistance to a minimum and thus greatly improved the performance of machinery. However, even though a similar development in the field of linear motion would have been ten times as valuable, linear motion through rolling contact was a long time in coming.

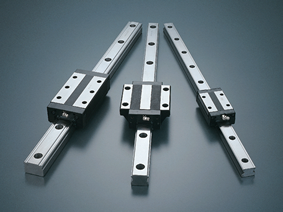

THK solved the problem, previously considered too difficult, of linear motion with rolling contact by applying its unique technological capabilities, and in 1972, it became the first company in the world to develop and commercialize the Linear Motion (LM) Guide. Our linear motion system enabled rapid improvements in the accuracy, speed and labor-saving potential of advanced mechatronic instruments. With THK's LM Guides, machine tools and industrial robots become capable of ultra-precise operations, and semiconductor-manufacturing devices can operate in submicron units. More recently, the system has been applied in liquid crystal manufacturing lines, railway carriages, assistive vehicles, medical equipment, skyscrapers and residences, and amusement devices. The use of LM Guides has truly expanded beyond all prior boundaries.