October 19, 2022

October 17, 2022

Cross-Roller Ring Model RBU Added to Lineup

Solid Construction with Integrated Inner/Outer Ring Helps Reduce Installation Time

THK has expanded its cross-roller ring lineup with the Cross-Roller Ring Model RBU, which features a solid construction with integrated inner/outer rings that help greatly reduce installation time.

Cross-Roller Ring Model RBU

Structure and Special Features of the Model RBU

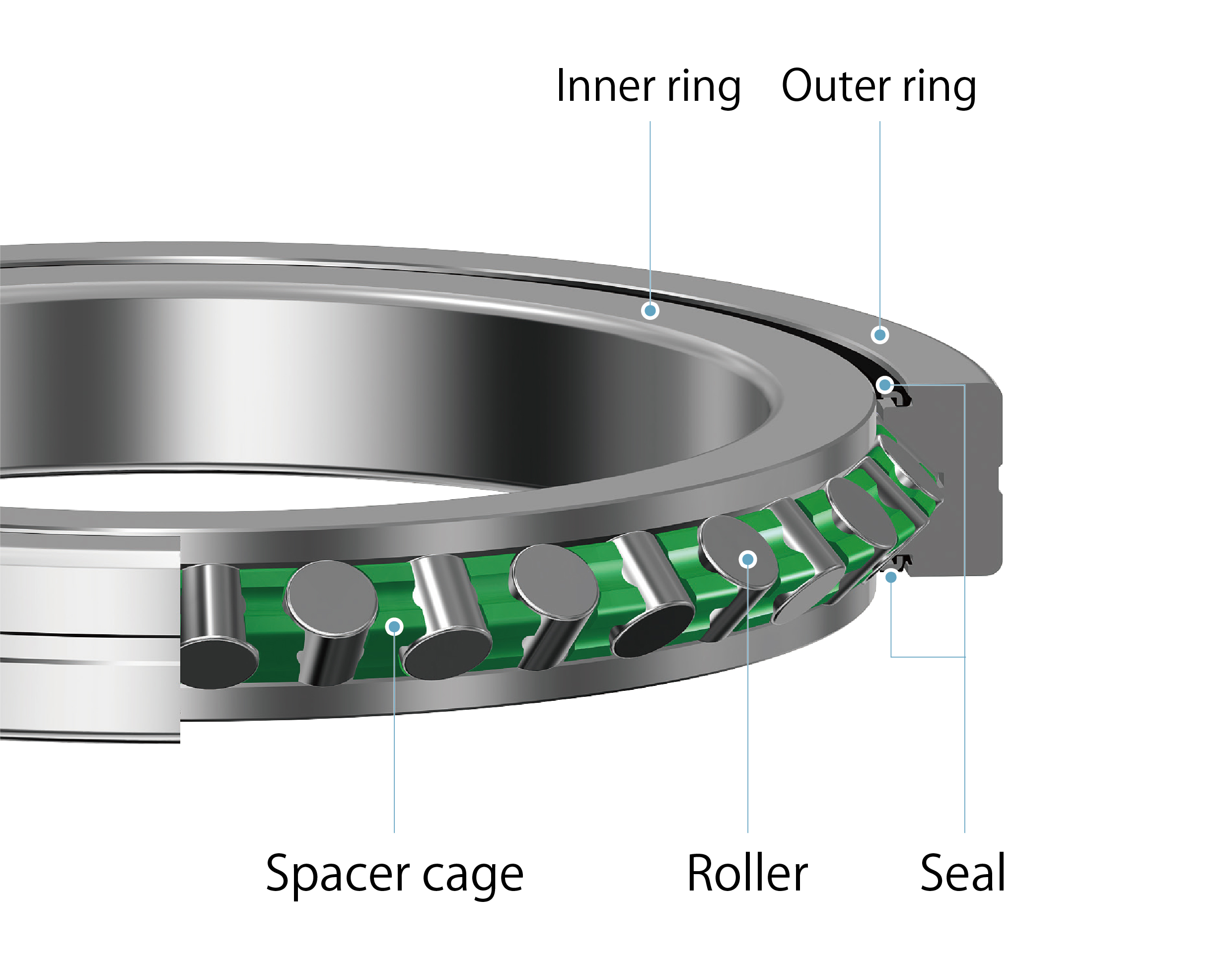

Cross-roller rings are roller bearings that feature cylindrical rollers arranged orthogonally with spacer cages between the inner and outer rings so as to facilitate load bearing in every direction (radial, axial, and moment loads) in addition to high rotational accuracy. The cross-roller ring, taking full advantage of those characteristics, has been widely adopted as a rotary bearing for equipment that requires high rigidity and high-precision rotary motion, such as industrial robots, machine tools, and reduction gears.

In recent years, industrial robot and reduction gear manufacturing plants, whose shipment quantities are increasing globally due to the push for automation and labor savings, have had to review and improve production processes in order to increase assembly efficiency. Furthermore, there is an urgent need to create systems that allow for even greater production increases with the same number of personnel. While cross-roller rings provide high-precision rotary motion, because they require a strenuous assembly process, gaining installation experience as well as increasing production efficiency has been a struggle until now.

To help reduce the installation time of cross-roller rings, THK has added the Model RBU to the lineup. This product features a stable, integrated inner/outer ring construction, and on the performance front, provides both consistent rotational accuracy and rotational torque. The product lineup has been expanded by a total of 24 models, with shaft diameters ranging from ø20 to ø190. Furthermore, the dimensions are interchangeable with the existing Model RB, so you can easily swap to the Model RBU without making any design changes.

Through the development of new, original products, THK will meet the automation and labor-saving needs of all industries, proposing solutions that will boost productivity and improve processes.

For availability please contact your local THK dealer.

Please create a free account to our Technical Support Site to download catalogs.

>Create a free account

Features

Simple Installation Adjustments

No detailed adjustments are needed when attaching to equipment, making installation easy and less time-consuming. For installation of industrial robot joints, rotating parts, and reduction gears, the time you save becomes greater the more pieces you produce.

Stable Bearing Performance

The integrated inner/outer ring structure improves component rigidity over the Model RB, which has a split outer ring. This mitigates the impact of the housing’s accuracy and rigidity, providing stable performance.

Exchangeable with Existing Products

The dimensions are interchangeable with the existing Model RB, so you can make the switch without any design changes.

Extensive Lineup

Product lineup expanded by a total of 24 models, with shaft diameters ranging from ø20 to ø190.

Please direct any media inquiries to:

|

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Unit, THK CO., LTD. Phone: +81-3-5730-3845 E-mail: thk-sp@thk.co.jp |