Adaptive Gripper Series TNH

With the new adaptive gripper series TNH, THK sets new standards in factory automation. Thanks to their ability to precisely grip workpieces of various shapes and sizes, these innovative grippers enable a significant increase in productivity when used with robots and handling systems.

.png)

Image 1 Adaptive gripper series TNH

The TNH series includes two models:

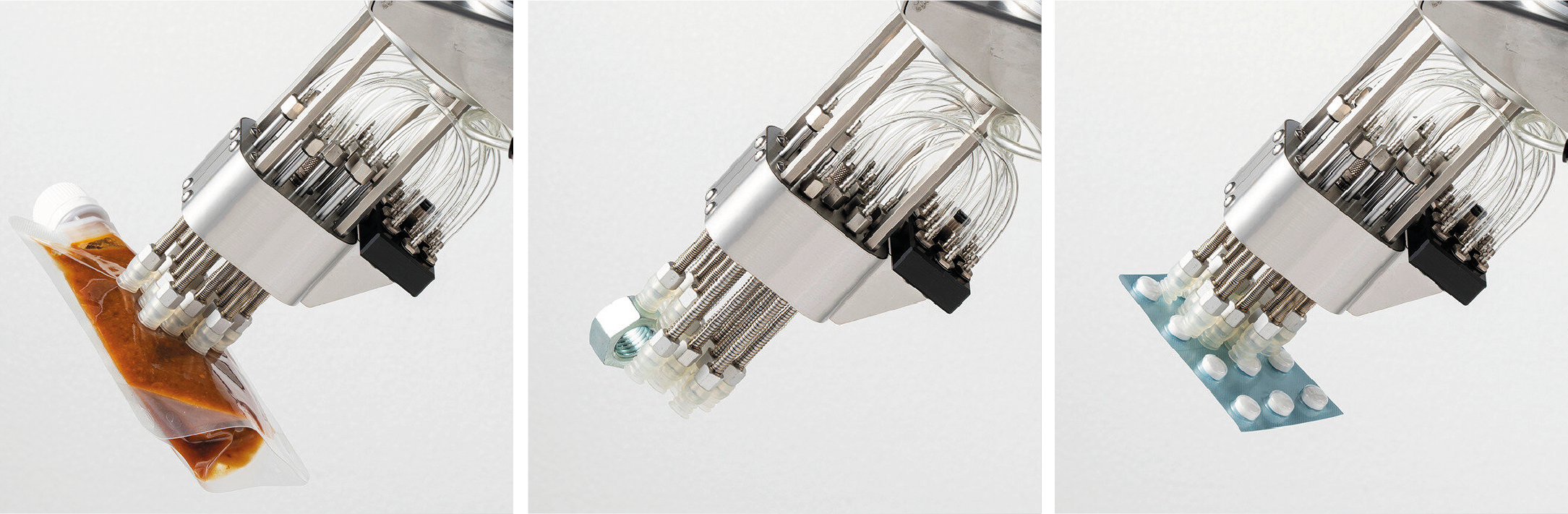

- Adaptive Suction Gripper: Equipped with 12 bellows suction pads and an integrated throttle valve, this gripper is ideal for suctioning workpieces with a wide variety of surface structures.

- Adaptive Gripper in paired arrangement: This unit enables the secure gripping of workpieces with varying shapes and offers maximum flexibility.

A key advantage of the TNH series is its versatility: there is no need to change the gripper for different workpieces. Even complex-shaped objects can be securely picked up, transported, and placed down with a single gripper.

The compact and lightweight grippers of the TNH series are ideal for use with collaborative robots and handling equipment. The mounting flange of the adaptive suction gripper complies with the connection dimensions specified by ISO 9409-1-50-4-M6. Featuring 12 individually lockable shafts, workpieces weighing up to 1 kg can be securely held, transported, and placed.

Image 2 Application examples for the adaptive suction gripper

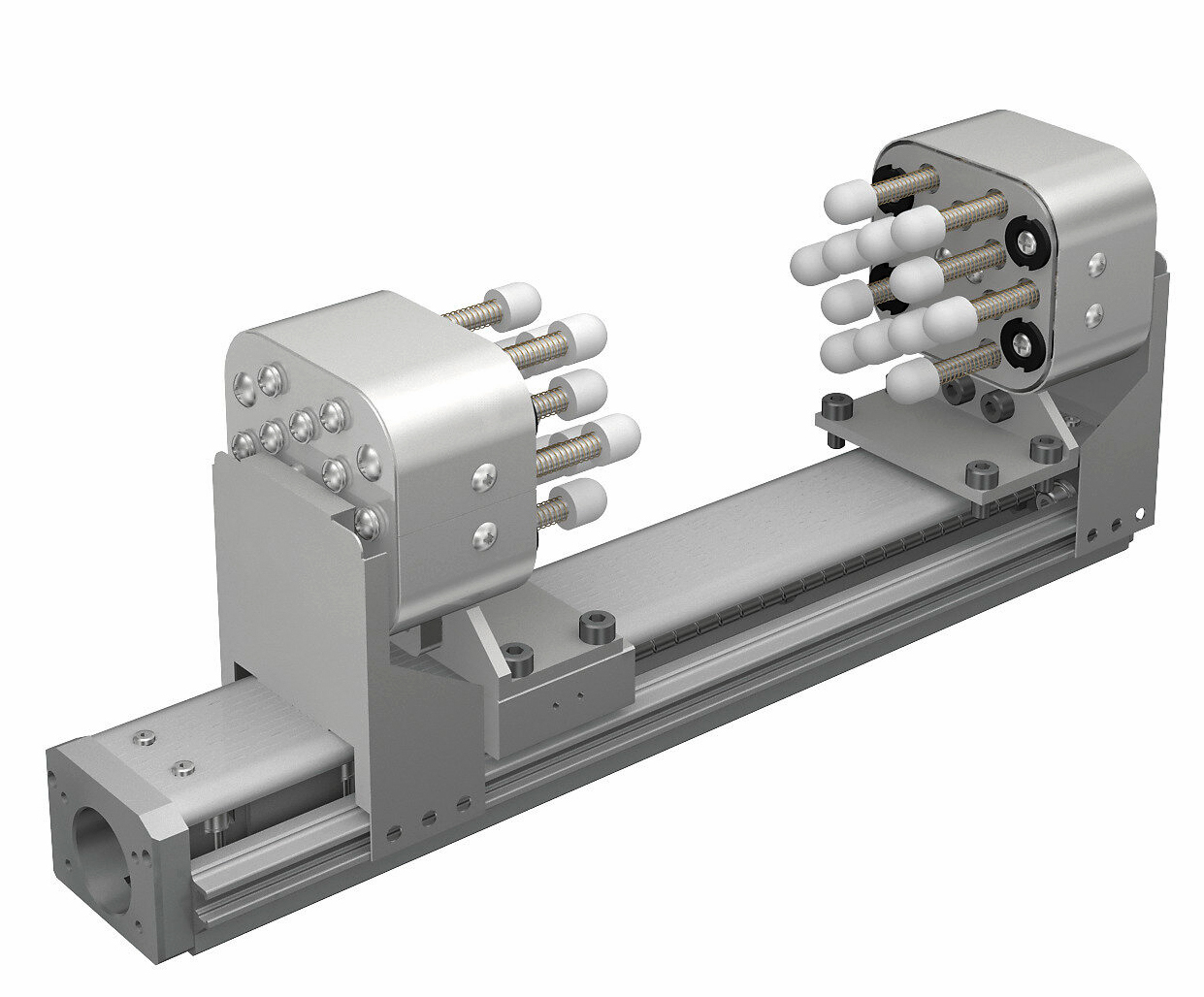

Image 3 Adaptive gripper unit (paired arrangement)

The adaptive gripper unit features a compact and lightweight mechanism that flexibly adapts to the shape of the workpiece. Silicone rubber at the shaft ends and an individual shaft stroke of 20 mm enable precise and secure gripping of workpieces weighing up to 1 kg. The release of the shafts is mechanically operated.

Left / Right hand ball screw actuator (e.g. KR-RL by THK) can be a good design combination with TNH to realize “paired arrangement”.

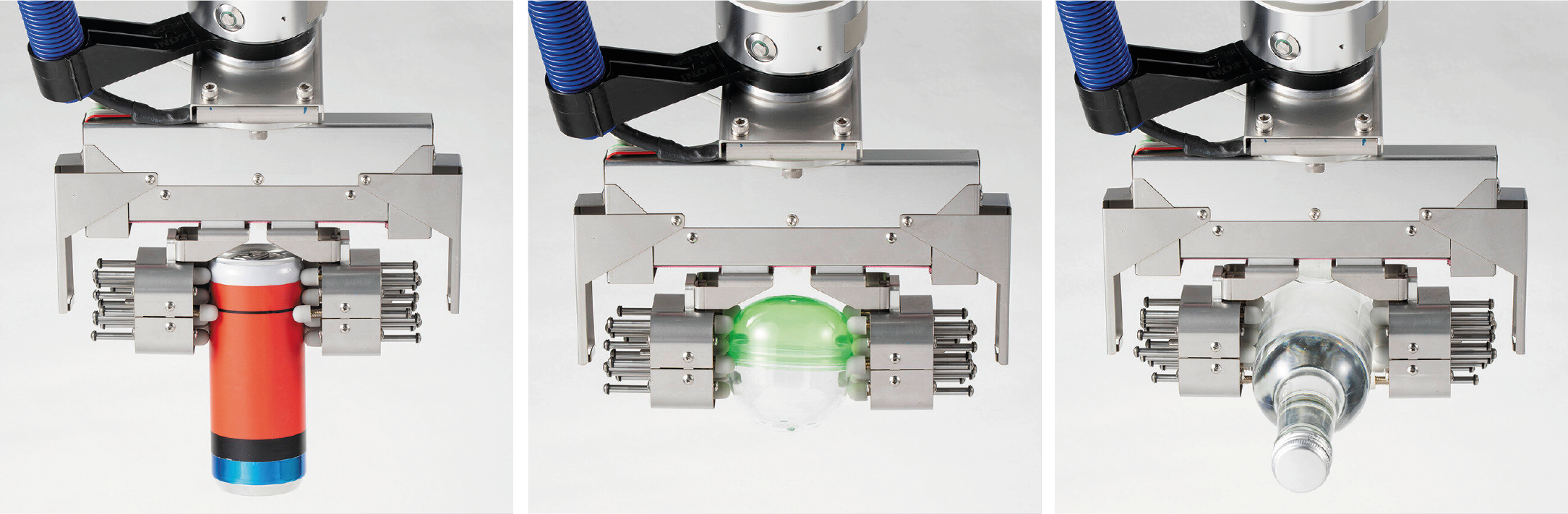

Image 4 Application examples for the adaptive gripper (paired arrangement)

Application video for Robot Hand/Gripper

https://www.youtube.com/watch?v=GPdWacUYwXM