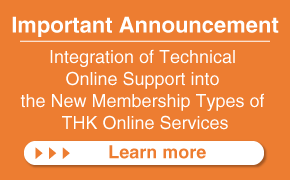

New Ready-to-install Precision Ball Screws SDA-VZ with End Machining and Support Bearings

With the new SDA-VZ series, THK offers precision ball screws with standardized end machining and corresponding support bearings. This reduces design and assembly times for these proven ball screws. The special ball circulation system with tangential ball return allows rotational speeds of up to 5,000 min⁻¹ (DN value: 100,000) to be achieved while maintaining stable torque.

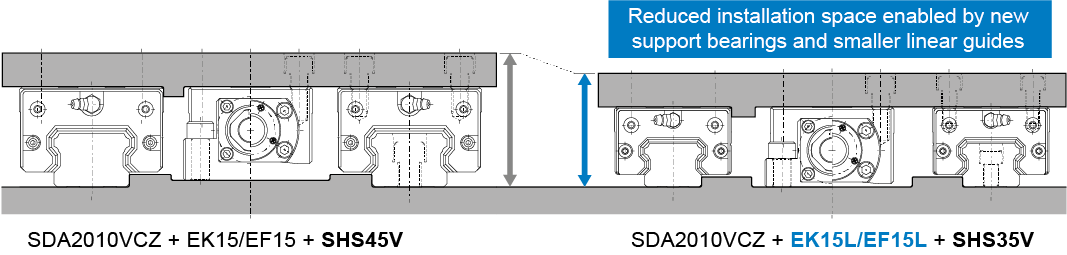

Illustration 1 Ready-to-install precision ball screws of the SDA-VZ series with EK-L and EF-L support bearings

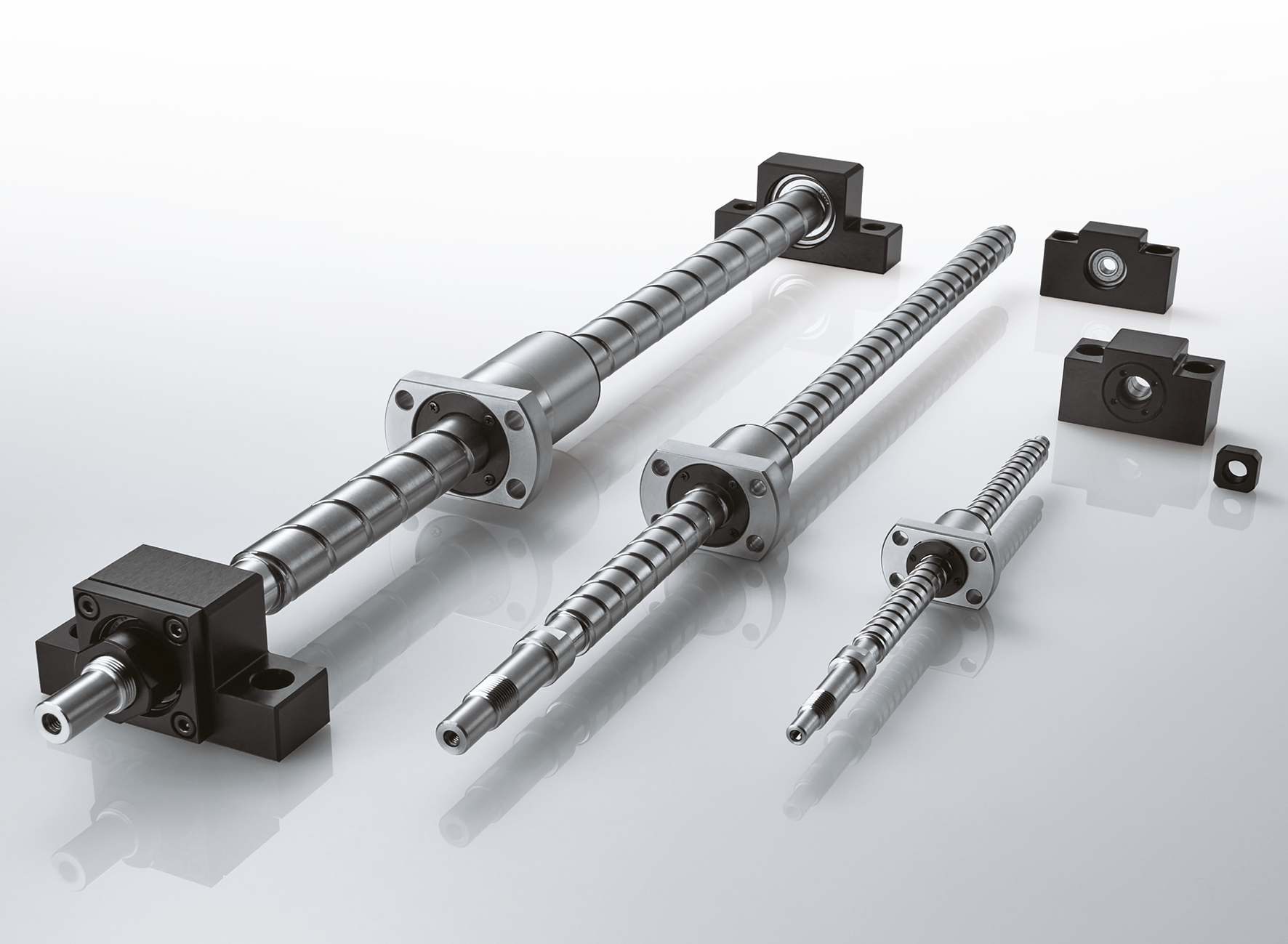

Another advantage is provided by the newly introduced support bearings EK-L and EF-L, which compared to the previous support bearings, allow a lower height of the spindle's center axis and enable the selection of smaller sizes for linear guides.

Illustration 2 Height comparison of the spindle's center axis with conventional support bearings and the new EK-L and EF-L support bearings

Illustration 3 Reduced installation space enabled by new support bearings with the option to use smaller linear guides

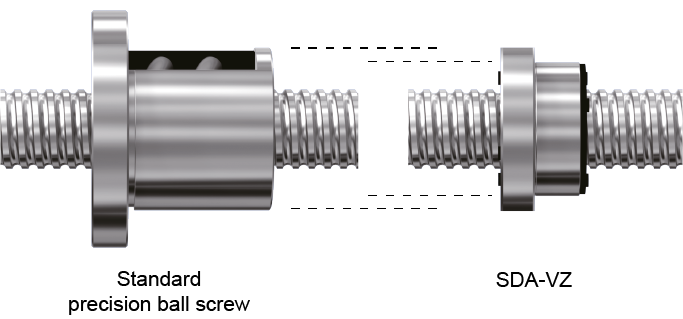

In combination the SDA-VZ ball screw features a nut with an outer diameter up to 30% smaller, this contributes to more compact systems and machines across a wide range of applications.

Illustration 4 Comparison of a standard precision ball screw with the smaller SDA-VZ type

To meet the diverse requirements of customers THK offers the SDA-VZ series in a total of 151 variants with spindle diameters ranging from 10 to 25 mm. The nut's external dimensions for spindle diameters of 10, 12, and 25 conform to ISO standard 3408.