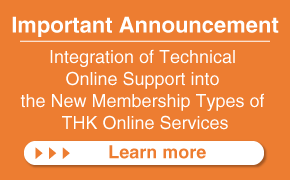

Space-saving ball splines for high-speed operation

With the ball splines or torque shafts of the LT-X, LF-X, and LTR-V models THK presents anti-rotation linear guides designed to transmit torque and linear motion using a single shaft. Thanks to the new ball circulation system between the raceways on the shaft and the recirculation in the nut, these ball splines are also suitable for high-speed operation.

Illustration 1 Space-saving ball splines of the LT-X, LF-X, and LTR-V series for high-speed operation

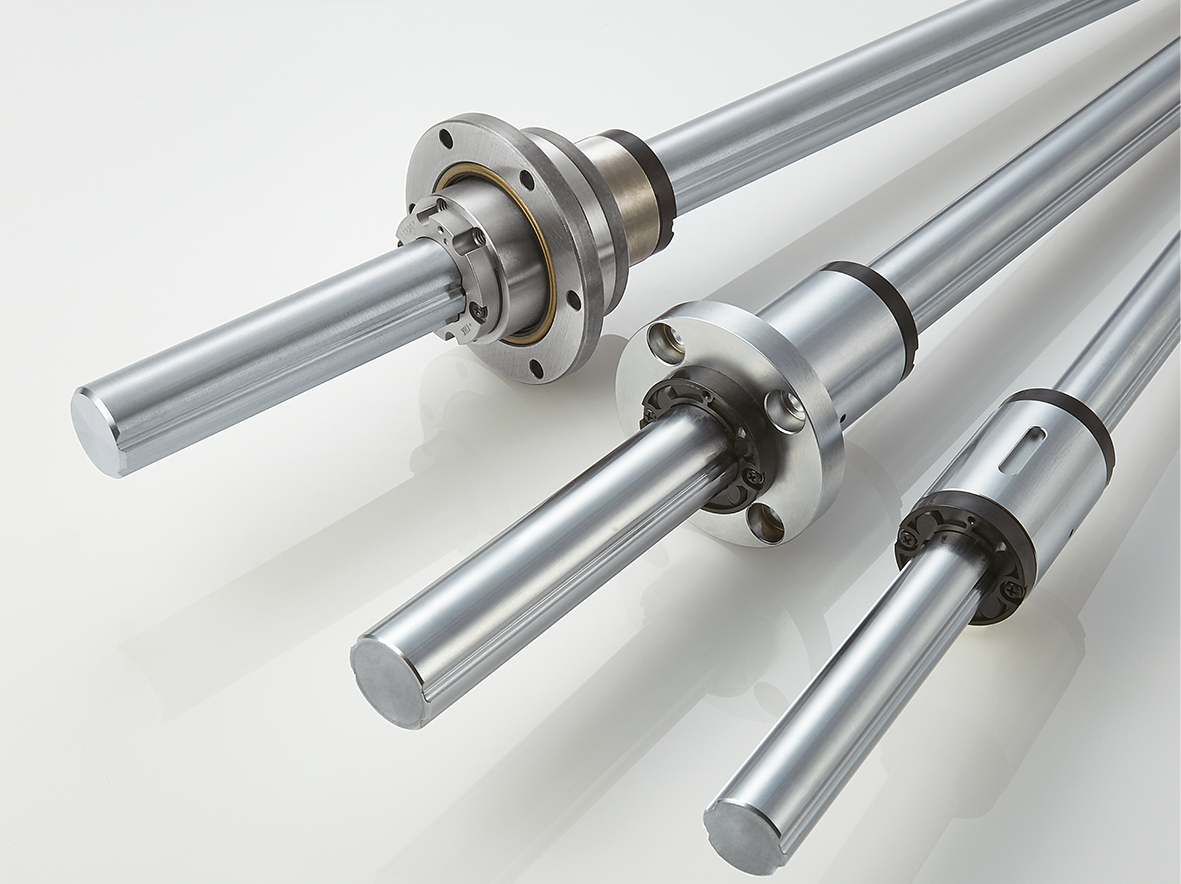

Enables significantly more compact designs

The nuts of the LT-X and LF-X models have an outside diameter that is 20% smaller than the previous LT and LF models. This enables significantly more compact designs and thus a reduction in the overall machine design.

Illustration 2 Comparison of the nut outer diameters of the LT and LT-X models

Suitable for high-speed operation

The new ball circulation system optimizes the ball circulation between the load area in the raceway grooves and the ball return in the nut and enables operation at a speed of up to 2 m/s with an acceleration of 49 m/s². In a long-term test a running distance of 10,000 km was achieved at these values without abnormal wear.

Improved running characteristics

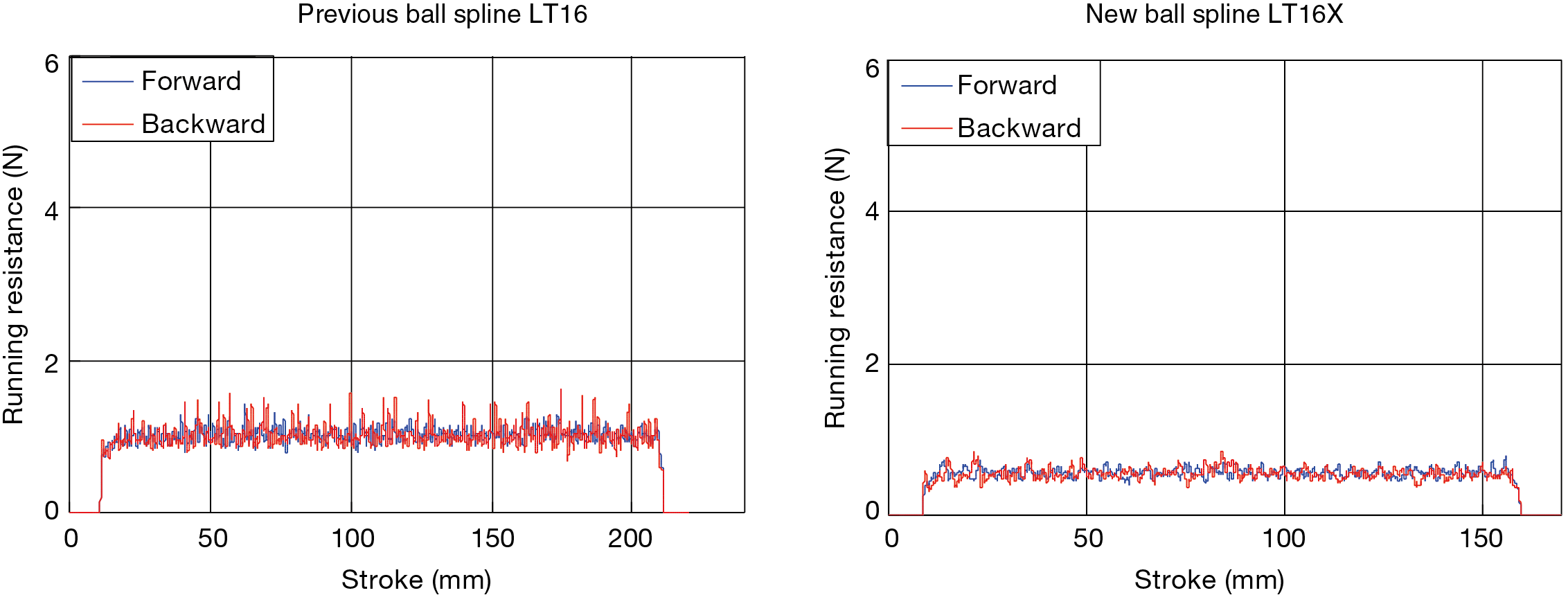

The optimized ball circulation guarantees smooth running characteristics and also reduces the fluctuations in the sliding resistance compared to the previous LT and LF models, as shown by a comparison test at a speed of 10 mm/s under identical conditions.

Illustration 3 Fluctuations in the sliding resistance of the previous and new model

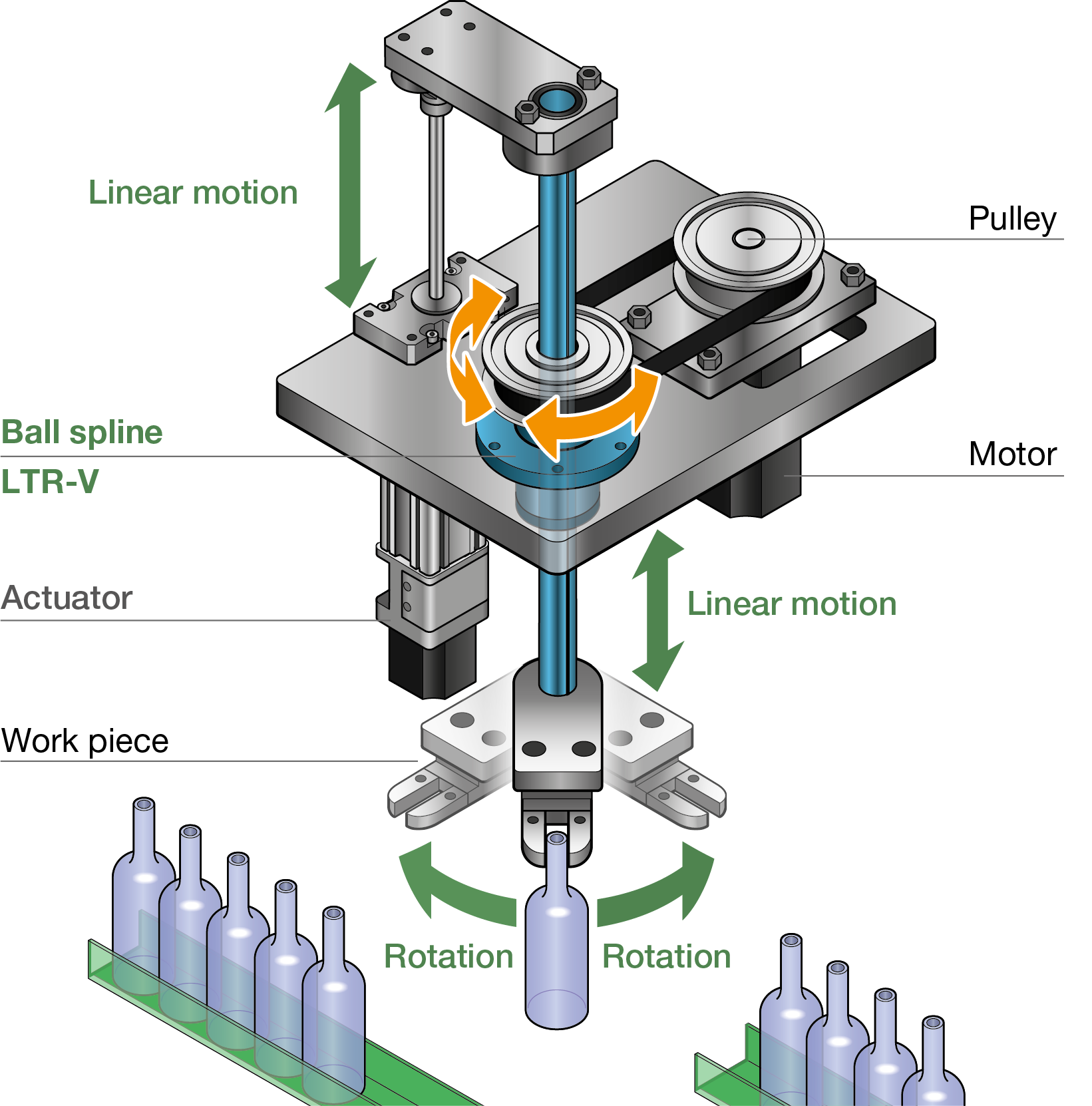

Rotary ball spline LTR-V

In this rotary ball spline, for simultaneous rotational and linear motion, the nut and support bearing form a single unit. The new LTR-V model, based on the LT-X model, is even more compact and lightweight compared to the previous LTR-A model.

Illustration 4 Application example with the LTR-V model for linear and rotational movements

Available models and sizes

The LT-X and LT-F ball splines are available as standard with shaft diameters from 3 to 30 mm and static torque ratings from 0.42 to 319 Nm. The rotary ball spline is available with shaft diameters from 16 to 25 mm and static torque ratings from 68.6 to 207 Nm.