December 02,2022

“OMNIedge” Now Provides a Tool Monitoring AI Solution that Detects Cutting Tool Damage and Wear to Reduce Loss

THK is now offering a tool monitoring AI solution for its “OMNIedge” IoT service for the manufacturing industry.

OMNIedge is THK’s IoT service that offers solutions for reducing loss that occurs on the manufacturing floor and improving overall equipment efficiency (OEE). Beginning as a service for linear motion components such as the LM Guide, ball screws, and actuators, OMNIedge has since expanded the coverage of its component failure detection AI solution to include rotary components such as motors and pumps for process automation and utility equipment. Now, THK is offering a tool monitoring AI solution, which can be retrofit onto equipment and requires no cumbersome setting of thresholds, in order to solve the challenges surrounding cutting tool use in machine tools.

Cutting tools present several unique challenges for a manufacturing operation: How to reduce tooling costs while managing tool life in the optimal manner? How to avoid losses incurred by machining defects and rework due to damage and chipping? Previously, the cardinal rule was to replace tools based on the piece count before machining defects would start to occur. Due to the safety factor built in, this meant that tools would often be replaced while still in good condition, leading to a relative increase in costs. That is why THK has developed a simpler AI solution that can be implemented right away.

Of special note is the fact that its ability to be retrofit onto machines allows this system to be easily implemented on machine tools currently in use, even if their model years or manufacturers vary. The system can also detect cutting tool damage and chipping in addition to monitoring wear, which helps businesses that perform large volumes of machining work to optimize tool life, decrease tool replacement costs, and reduce rework loss when machining defects happen, so users can expect to achieve high cost performance. The AI automatically analyzes data collected from the sensors and detects abnormalities, which means its accuracy increases with repeated use.

THK will continue to incorporate feedback from users in order to expand the service in a way that best suits user needs and will help their manufacturing operations achieve continuous productivity improvements.

Features

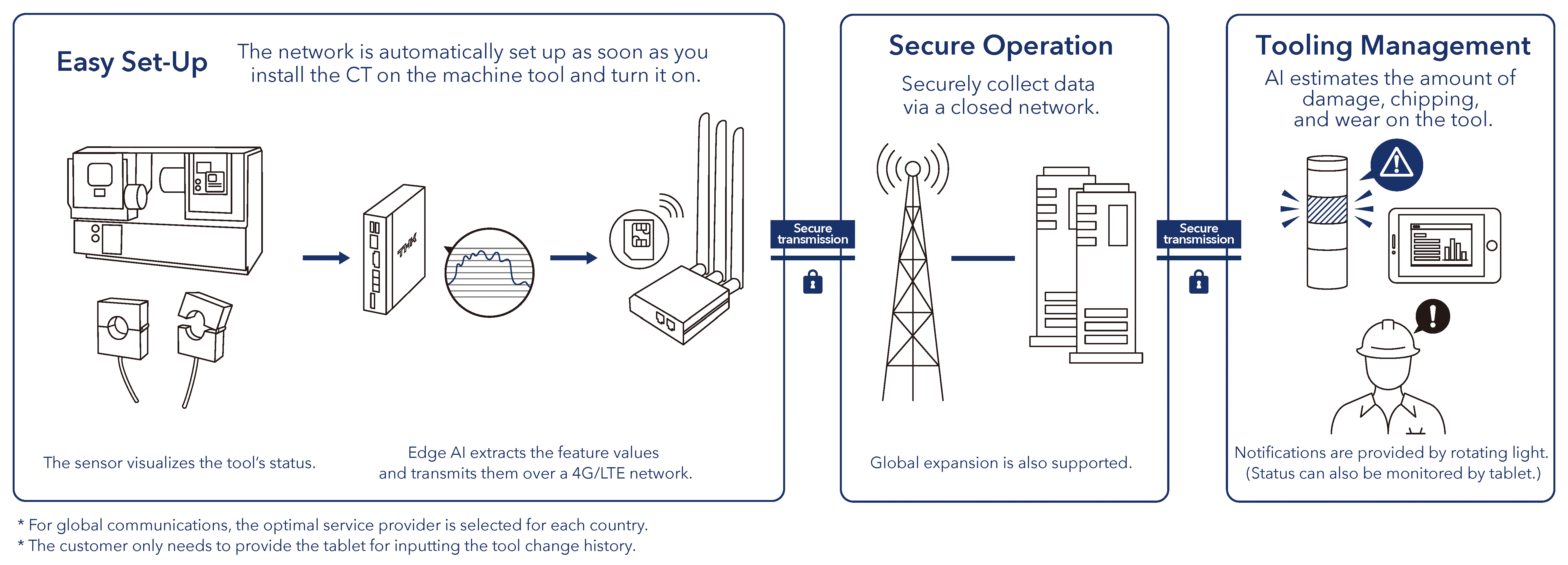

Installing Sensors onto Existing Equipment Is Easy

To install, all you have to do is clamp a CT (current sensor) onto the motor cable. A CNC connection is not required, so it is compatible with machine tools regardless of the model year or manufacturer.

Ready-to-Use Software

The setting tool does not require any difficult configuration, so you can begin monitoring and collecting data from the day you install it.

AI Evolves to Rapidly Improve Accuracy

The AI analyzes data automatically to detect abnormalities, so it becomes smarter the more it is used.

OMNIedge: An IoT Service for Manufacturing

Service Overview

OMNIedge is THK’s IoT service that offers solutions for reducing different types of loss that occur on the manufacturing floor and improving overall equipment efficiency (OEE).

Phase 1: Predictive failure detection AI solution for linear motion components (available now)

Phase 2: Predictive failure detection AI solution for rotary motion components (available now)

Phase 3: Tool monitoring AI solution (new)

The package combines the sensor and other hardware with a communication device, and communication fees are included, which makes the service simple, secure, and available for a reasonable price.

Start of Shipping

Starts at the end of November 2022

OMNIedge Website

https://www.thk.com/omniedge/en

OMNIedge Tool Monitoring AI Solution Configuration

THK provides all the infrastructure you need, from the sensor to the communication environment, including the SIM card.

*For global use outside of Japan, please consult THK.

Related News

- July 29, 2022 OMNIedge, an IoT Service for Manufacturing, Now Supports Private Cloud

- February 09, 2022 OMNIedge, an IoT Service for Manufacturing, Now Provides Predictive Failure Detection for Rotary Components

- November 30, 2021 Global SIM Compatibility for the “OMNIedge” IoT Service for Manufacturing Now Available in Taiwan and Singapore

- August 5, 2021 Two Bonus Features Now Available to Add Peace of Mind to the “OMNIedge” IoT Service for Manufacturing

- July 21, 2021 OMNIedge, an IoT Service for Manufacturing, Officially Launches in China

- May 24, 2021 The “OMNIedge” IoT Service Now Available for Actuators

- April 29, 2021 The “OMNIedge” IoT Service for the Manufacturing Industry Now Connects with FIELD system: Bolstering the Service with Industrial

- April 22, 2021 The “OMNIedge” IoT Service for the Manufacturing Industry Goes Global: A New Service Compatible with Global SIM

- April 15, 2021 The “OMNIedge” IoT Service for the Manufacturing Industry: Service Now Available for Ball Screws